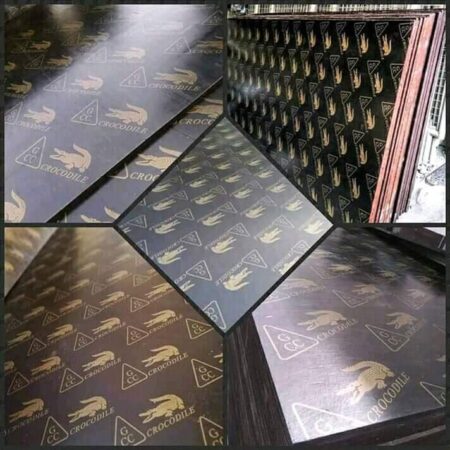

What is Black Oxide?

Black oxide, also known as blackening or black oxide coating, is a chemical conversion process that transforms the surface of ferrous metals (like steel and iron) into a black oxide layer, primarily magnetite (Fe3O4). This process not only provides a visually appealing matte black finish but also enhances the material’s resistance to corrosion and wear.

Applications of Black Oxide

Black oxide coatings are widely used across various industries, including:

-

Automotive and Aerospace: Used for engine components, suspension systems, and landing gear to improve durability and corrosion resistance.

-

Tools and Hardware: Commonly applied to hand tools, fasteners, and cutting accessories to enhance grip and reduce glare.

-

Industrial Equipment: Utilized in machinery and equipment to extend the lifespan of components exposed to harsh environments.

Benefits of Black Oxide Coating

-

Corrosion Resistance: The black oxide layer acts as a barrier against rust and oxidation, significantly improving the longevity of metal parts.

-

Aesthetic Appeal: Provides a smooth, matte finish that is visually appealing and suitable for decorative applications.

-

Reduced Light Reflection: The non-reflective surface is beneficial for applications involving optical instruments and UV/IR sensors.

-

Minimal Buildup: The coating process results in minimal dimensional changes, making it ideal for precision components.

Black oxide or blackening is a conversion coating for ferrous materials, stainless steel, copper and copper based alloys, zinc, powdered metals, and silver solder.[1] It is used to add mild corrosion resistance, for appearance, and to minimize light reflection. [2] To achieve maximal corrosion resistance the black oxide must be impregnated with oil or wax. [3] Dual target magnetron sputtering (DMS) is used for preparing black oxide coatings. [4] One of its advantages over other coatings is its minimal buildup.